Raw material supply

Raw materials procured according to ISO EN 10263 standard are stored and checked according to the specification requirements.

Surface Treatment

We have 8-station phosphating facility where we make zinc phosphate coating to prepare raw materials for rolling and production operations. We have a purification system working depending on our surface treatment facility.

Wire Drawing

It is to make the raw material suitable for production by calibrating (rolling) the diameter required by the production.

We have 3 rolling machines.

Production

Automotive companies have become one of the important actors of the sector in this regard by forming a large part of the production within BOLT Fasteners CO.

Heat Treatment

We have a Tofaş approved heat treatment furnace with a total of 1250 kg / h capacity (750 kg / h and 500 kg / h) with 2 plc controlled dephosphate systems.

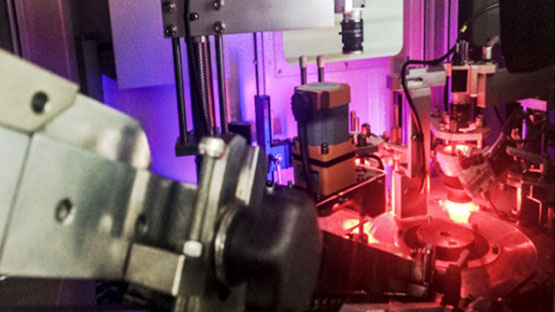

100% Control Section

100% control section is divided into 2 parts as machine control and visual control.

100% Control Area with a total of 86 m² area; 30 m² is the machine park and 56 m² is the visual control park.

There are 3 sorting machines in the department, which operate with an average speed of 100 pcs/min with 4,4 and 7 cameras. We have 5 special screened sorting stations in the visual control section.